Two questions first: "What kind of hoist do I need?" & "How do I select a hoist".

When you read this article, you should have known about hoist and planned to purchase it, but you just don't know how to choose the most suitable one. Indeed, choosing the right electric hoist for your own factory or customer is a complicated and confusing thing. Today we will answer the above two questions to make the matter of "purchasing a hoist" a very fulfilling thing. The content of this article is very practical. If it is useful to you, please bookmark it. Of course, you can also share it to help more people.

Before we start, let's check a request sent by a customer:

"Hello, I need a 5 tons electric hoist with a lifting height of 9m. My voltage is 220V 3Phase 50Hz. I need to hang it on the H-beam in the mold shop to lift the mold. The hoist should can move on the beam. It’s better to equip it with a remote control so that I can operate it easily. I have a requirement for speed. It can be raised and lowered slowly, also can be fast, so that I can use it to help me place the mold accurately according to my rhythm. Please send me your quotation."

How about it? The customer knows his needs very well. He knows what kind of electric hoist can meet his requirements. After reading this article carefully, you can also easily choose the right electric hoist just like this customer.

Hoist

Hoist is a tool, a small and light lifting equipment, which is mainly used as a lifting mechanism for lifting materials. It is widely used in every manufacturing unit, also in construction, factories, workshops, and cleaning industries with different uses.

According to the different driving power, hoists can be divided into 4 categories: manual chain hoist, electric hoist, pneumatic hoist and hydraulic hoist.

Chain hoist

It is suitable for short-distance lifting of small equipment and goods. Manual hoist normally is a chain hoist. They can be operated with a lever to reduce the applied force, or directly by pulling the endless chain in one direction or the other to drive the pulley, which receives the hoisting chain by gear reduction. The lifting weight of this type hoist is generally no more than 10T, the largest can reach 20T, and the lifting height is generally no more than 6m. If you need to use the hoist occasionally, or need to use it in a place without power, you should choose a chain hoist. The manual hoist has the advantages of compactness and lightness.

Electric hoist

It is a hoisting equipment powered by an electric motor. If you have to use the hoist frequently and your operation needs to be precise, you should choose an electric hoist. Electric hoists are usually equipped with a lifting speed adjustment system or at least two operating speeds (slow and fast) and emergency brakes. Slow speed is used to accurately locate the load. Electric hoists can lift loads very accurately, but they are not designed for continuous operation. Most electric hoists allow a higher lifting height than manual hoists, and can usually be divided into electric wire rope hoists and electric chain hoists.

Pneumatic hoist

Pneumatic hoist is the most ideal explosion-proof lifting equipment in the world. Pneumatic hoists need to be supplied with compressed air, and they are used in explosion-hazardous areas (ATEX areas). The pneumatic hoist is quiet, sturdy and precise. They are dust and moisture resistant, but the air filter needs to be cleaned regularly. The lifting speed of the pneumatic hoist is much faster than that of the electric hoist. If there is no compressed air network, these cranes need to be connected to suitable air compressors. Due to the good explosion-proof performance of the pneumatic hoist, it is widely used in industrialized countries such as petroleum, chemical, textile, painting, logistics, docks and other flammable, explosive, high temperature, high dust, and strong corrosive workplaces. Because of its high frequency and infinitely variable speed characteristics, it is favored by manufacturing industries such as automobiles, tractors, electric motors, refrigerators, etc., as well as logistics industries with large output and strong continuous operation.

Hydraulic hoist

Hydraulic hoist is a sturdy and quiet product that can operate in extreme conditions and areas with high risk of explosion. The hydraulic hoist needs a suitable hydraulic power source nearby. They have a high lifting capacity, so they can lift very heavy loads.

Which type of hoist should I choose?

Now that you know the hoist type, which type of hoist is right for you? You can refer to the following criteria to make a judgment:

- Do you want to use it frequently? For occasional use, you can use a manual hoist to reduce costs.

- Is the load heavy? The load you are going to lift will determine the type of hoist you need to buy. As a general rule of thumb, hand chain hoists are preferred for lifting capacities less than 10 tons. But it does not apply to high lifting heights. In order to lift a greater weight, an electric hoist is suitable. Therefore, according to your industry needs and requirements, the choice of hoist will be different.

- Speed. If speed is your working standard, you should exclude manual chain hoists and give priority to electric hoists.

- Whether the load to be raised or lowered allows you to operate at close to the chain.

- Is there a requirement for accuracy? Electric hoist will be recommended for high precision.

- Is the lifting height high? For example, 12m. The lifting speed of the manual hoist is slow, and it is not recommended to use it when the lifting height is high.

- What kind of driving force can you provide? Is it manpower, electricity, or something else? Electric hoists save manpower and are more efficient, but the price will be higher; chain hoists may require multiple people to operate, and the labor cost will be higher.

- Whether the working environment is a special environment, such as flammable, explosive, high temperature, high dust, and highly corrosive workplaces.

Combining the definition of hoist classification and the above standards, I believe you can already choose which type of hoist can meet your needs. In the next step, we will continue to in-depth detail what kind of hoist you need.

Determining factors of hoist specifications

- Lifting capacity. This is the first and most important factor to consider. When selecting a hoist, the rated capacity should be at least as high as the weight of the heaviest load to be lifted and no higher than the rated capacity of the pad eye, monorail system or other overhead structure from which the hoist will be suspended. Usually, our hoist must have a lifting capacity of at least 1.1 times the rated capacity during the dynamic load test and at least 1.25 times the rated capacity during the static load test to ensure the performance and quality of the product.

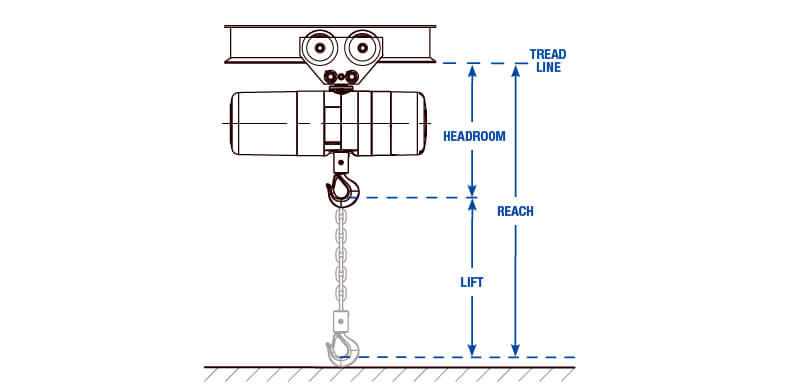

- Headroom. Headroom refers to the distance from the hoist suspension point to the fully raised hook saddle. For a hoist with a top hook, the headroom dimension is the distance between the saddle of the top hook and the saddle of the fully raised bottom hook. Before purchasing a hoist, we usually advise customers to consider the height of the facility where the hoist will be installed. If you need to maximize the lifting height, the lug option with extremely low headroom is the best choice.

![hoist height]()

- Lifting height. Lifting height is the distance that the load/bottom hook can move between its fully lowered and fully raised positions, that is, the distance by which your load is lifted or lowered.

- Speed. If high production is your goal, then a faster lifting speed will be required to get the best possible return on investment on your chain hoist purchase. If you are simply offloading delivered goods and shifting them sporadically then look at a more modest speed. Generally speaking, faster lifting speeds are preferred for long lifts or for shorter lift applications in which a high number of lifting/lowering cycles must be completed in a relatively short period of time. Normally, the standard lifting speed set by our hoist is can meet the needs of most customers. If you have a special speed requirement, you can specify it in your requirement.

- Does it need to be fixed? Or is it running? Here you have to clarify how the hoist operates. If you just need it to be fixed there for lifting/lowering the load, then you can choose a fixed hoist; if you need it to run around on the beam, you need to choose a hoist with a trolley.

- Power supply. If you choose manual hoist, please ignore this item. This part is for electric hoist. Larger factories and industrial workplaces usually use three-phase power; the three-phase voltage ranges from 220 to 575V. Conventional electric hoists are all using 3-phase electricity to meet most industrial needs. For home workshops, garages and some light manufacturing facilities, single-phase electricity is more common (110, 220, 230vac). At this time, you can choose single-phase electric chain hoists. Normally, the optional lifting capacity of single-phase electric hoists is 500kg-5000kg, which is not very large, but it can meet the demand.

- Working level. The working level mainly characterizes the operating load and frequency of use of the electric hoist. If it is often full load and frequently used, the higher the working level of the electric hoist is required. Please click here to know how to caculate the working level.

- Working environment (whether it is a special environment). The standard hoist is designed for "normal operating conditions", such as an indoor temperature of 20°C. Conditions such as extreme temperatures, unprotected outdoor areas, salty marine environments, corrosive environments, classified hazardous areas, clean rooms, and washing areas may require a hoist specially designed or modified for these environments.

- Control modes. At present, the hoist has two control modes: pendant control and remote control. The pendant control is a standard configuration by default, which is to connect the pendant and the electrical control box on the hoist through a control cable. Therefore, when operating hoist running on the beam, the operator also needs to move with it. In contrast, remote control is more convenient. After installing the receiver on the hoist, the operator can control the electric hoist through the transmitter in his hand. The radio control pendant can also be smaller, lighter and more ergonomic. Of course, you can also configure these two control modes for your electric hoist at the same time.

![hoist control modes]()

- Control voltage. The control voltage of the hoist is usually relatively low, the common ones are 24, 36, 48V. In some countries, the hoist control voltage is designed to be 110V, which is already very high. In comparison, low voltage is safer for operators.

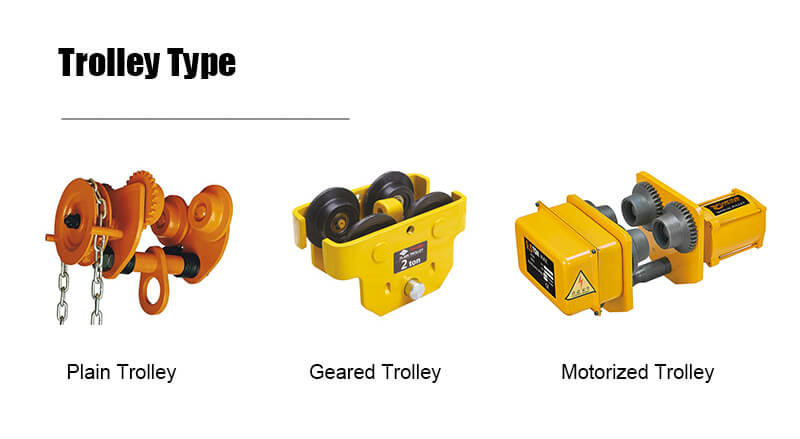

- The type of trolley. If you have to move a load from one place to another, then you need to learn about trolleys. For a hoist with a lighter load, you can choose a manual trolley. If the load is heavier and the running speed is required, an electric trolley is a good choice. It is also very important to choose the right trolley. For the type of trolleys, please refer to the figure below.

![hoist trolley type]()

Plain Trolley: Also known as a push/pull trolley, a plain trolley is the simplest form of trolley available. As discussed above, the hoist will hang from this trolley by either a hook or lug mount. A plain trolley will move the chain hoist along the Beam by human power via the hoist operator. The operator will grab either the hook or the item being lifted and pull or push the item to move it in the desired direction along the Beam.

Geared Trolley: A geared trolley is the next step up in ergonomics. With this option, the chain hoist operator will pull on a chain hanging from the trolley (much like a manual overhead door operator), and the trolley will use its gears to roll the trolley wheels along the Beam instead of human push/pull power as we discussed with the plain trolley.

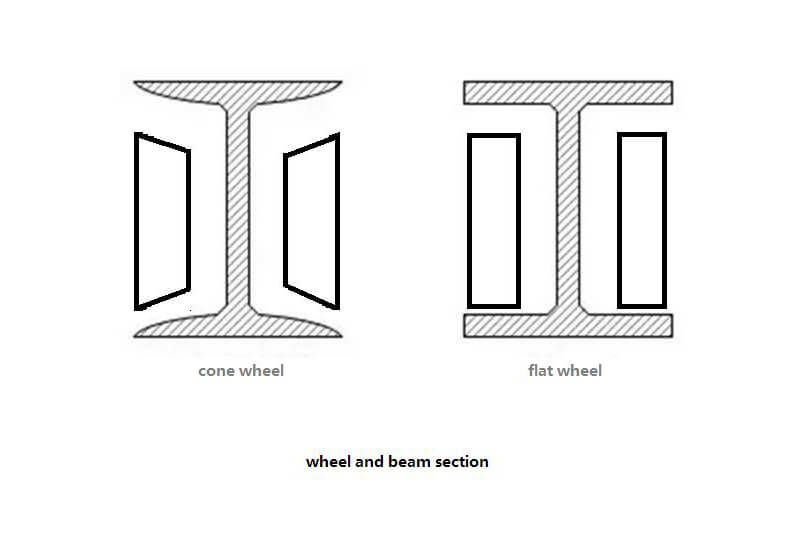

Motorized Trolley: The motorized trolley option is the most ergonomic of all the options we’ve covered. This option is exactly what it sounds like, instead of a plain push/pull trolley, or manual geared trolley, this trolley will have a motor attached to the side of the trolley wheels. A motorized trolley can have its own control pendant that will hang down from the beam in close proximity to the chain hoist pendant. Another option is to have a qualified installer wire the trolley into the chain hoist and bring the controls down to the same pendant control used by the chain hoist itself; keeping all controls on one push button station, and thereby creating a more efficient and ergonomic operator environment. - The type of beam. There are two most common monorail beams, I-beam and H-beam. As shown below. Please check carefully which type of beam you want to hang hoist. When buying a hoist, if it is an I-beam, you must inform your hoist supplier of the height, flange width and taper of the beam, so that the hoist supplier can match the right wheel.

![wheel and beam section]()

- There may be needs in the future. A 5-tonne hoist may be suitable to lift your items now, but what about your future needs? Do you see yourself lifting heavier objects in future than you are today? It wouldn't be cost-effective to go back to the shop every time you want some things lifted that happen to be heavier than your previous items. Go for something that can cater for both your present and future needs.

- Safety. Safety always comes first. Hoist is a kind of special equipment. Please make sure that your electric hoist has at least overload limiter, lifting limit, thermal overload protection and electrical protection device.

- Warranty. In order to avoid repair costs, you must purchase products with attractive warranty features. This period is usually 1 year, but it may vary. Obtain a written warranty from your service provider, and as mentioned above, please make sure that the supplier is capable of fulfilling the warranty with trained staff and spare parts.

- Budget. Budget is a factor that can never be ignored. However, it is important not to be short-sighted in this regard. Don't simply buy from the cheapest sources and hope to get the best, you need to make sure that your service provider has important support in terms of expertise and spare parts in case problems arise. If possible, check your supplier’s premises and convince yourself that they can meet your current requirements and any future requirements.

Knowing what type hoist you need, and keeping the above factors in mind, you can settle on the right hoist that you require. While making the purchase, you shouldn't hurry, after thinking twice, choose a product that will give you the best return on investment.

Get Free Quotation