Overhead Crane Needs of Myint

Myint is a visionary entrepreneur in Myanmar, a country in Southeast Asia that has a population of about 54 million and a GDP of about $64 billion. He runs a successful showroom that showcases and sells various products, such as furniture, electronics, appliances, and machinery. He wanted to expand his showroom and make it more modern and competitive.

New 3-story Showroom Under Construction

New 3-story Showroom Under Construction

New 3-story Showroom Under Construction

New 3-story Showroom Under Construction

He decided to build a new three-story showroom that would have more space and facilities for his customers. He planned to install three bridge cranes in his showroom, which are overhead cranes that can move heavy loads across a rectangular area. He thought that bridge cranes would help him display his products more effectively and creatively, and also impress his customers with his innovation.

Contact Yuantai Crane

Myint asked his procurement Mrs. An who was in China to contact us, a leading bridge crane manufacturer in China, and told us about his plan. We discuss his crane needs with him, his engineers and procurement in WeChat group, which is very convenient. He asked us to provide him with a suitable bridge crane solution that would fit his new showroom. We were intrigued by his idea and eager to work with him.

We asked Myint to share us the structural design drawing of his new showroom, and we studied it carefully. We designed 3 Chinese traditional overhead crane solutions for him accordingly. However, Myint requested frequency conversion for both crane lifting and traveling. We suggested a European-spec overhead crane solution that used advanced and reliable technology. He was pleased with our proposal, but he had one concern: he was worried about the cost of purchasing the main girder for the three bridge cranes.

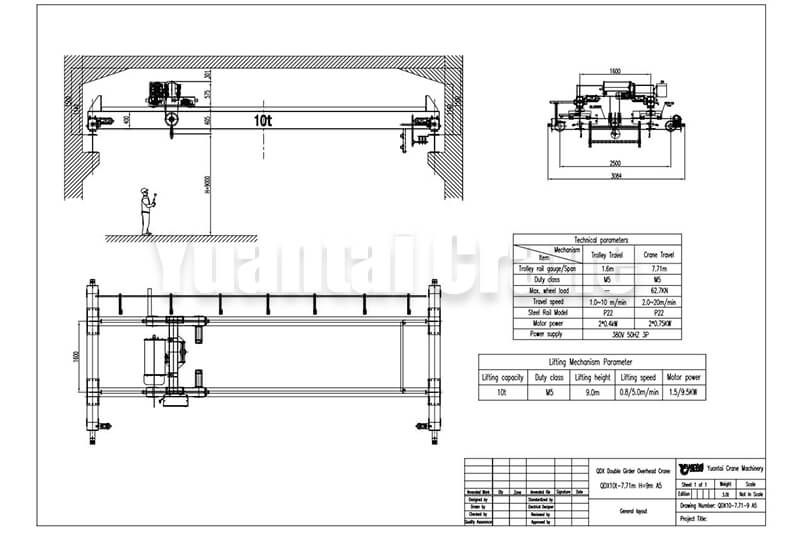

Drawing of 10 ton overhead crane with 7.71m span

Drawing of 10 ton overhead crane with 7.71m span

HD 3ton single girder overhead crane solution

HD 3ton single girder overhead crane solution

End carriages drawing of 10 ton overhead crane

End carriages drawing of 10 ton overhead crane

The main girder is the horizontal beam that supports the hoist and trolley. It is usually the biggest and heaviest part of the bridge crane system. He knew that buying the main girder from China would incur high freight fees, and he wanted to save money and time.

Myint had a smart solution: he decided not to buy the main girder from us, but to produce it locally in Myanmar. He contacted with some local steel manufacturers who could make the main girder according to our specifications. He thought this would reduce the cost and also support the local economy.

We were impressed by his initiative and resourcefulness, and we agreed to cooperate with him. We sent him our detailed specifications for the main girder. After some detailed communication, Myint arranged for his procurement in China and placed an order for these overhead cranes. Our team provided him with all the necessary technical guidance and support, ensuring that the cranes were installed and commissioned successfully.

The use of the European-spec crane solution was also a great choice. This solution is known for its advanced technology, high efficiency, and excellent performance. The frequency conversion for both hoisting and operation further improved the functionality of the cranes, making them more versatile and efficient.

Conclusion

In conclusion, Myint's decision to produce the main girder locally and use the European-spec crane solution was a smart move. It helped him save costs, support local businesses, and ensure that he had high-quality cranes that were efficient and reliable. At our company, we are committed to providing our customers with the best solutions that meet their specific needs. We are proud to have helped Myint achieve his goals and look forward to serving many more customers like him in the future.

We were looking forward to seeing his new showroom equipped with our overhead cranes, which we believed would enhance his business and reputation. We were honored to be part of his success story.

Get Free Quotation