We received very good crane product feedback from Tony's company, who have cooperated with us for twice. Let's check the beautiful photo of double girder bridge crane finished installation in his workshop.

The first crane Tony purchased from us was a traditional single girder overhead crane, but the experience given to him at the time was not good. Due to COVID-19, our engineers cannot go abroad for installation, so, the customer finished the single girder bridge crane installation with his team, but the crane was not working well.

"I have operated this crane since 2018 and had the overheating issue from the first day I ran it. The overheating only occurred after running the crane for 10-15 minutes. Adding additional resistors solved this issue."

Tony is very professional. By analyzing the cause of the failure, he solved it by himself. When he communicated with us about the new 40 ton bridge crane requirements, he gave feedback on this problem and hoped that he would not encounter this failure on the new cranes. Yes, our new crane solution we offered this time was an European-spec bridge crane which has a more intelligent, convenient and safe electronic control system. Before we discuss the new bridge crane solution, let's take a look at the client's situation.

Who They Are - Supporter behind the World's Famous Car Brands

The customer's company is an excellent enterprise. Die design and build are their main product and service. State-of-the-art tools and machines are equipped in their factory and every employee who mans those machines is more than fully qualified to do so. They construct their own dies using innovative machines and expert-level knowledge to ensure the quality of each and every product.

They offer a wealth of products, including personalized gages, prototypes, stampings, wire EDM, tools, dies and assemblies, all produced in-house.

Top-of-the-industry manufacturers and world-renowned companies have chosen his company products to produce anto parts. Their parts can be found on products made by TESLA, HONDA, NISSAN, UNIPRES, SUBARU, CHRYSLER.

A very good company in the Automotive Mold Industry.

Double Girder Bridge Crane Solution

- Lifting capacity: 40 tons

- Lifting height: 10.688 meters

- Crane span: 22.25 meters

- Power supply: 480V 60Hz 3Phase

- Quantity: 2 units

- Working duty: not mentioned, designed as FEM2M (ISO M5)

- Other requirement: Each crane will run on different spans but are the same length and width.

United States 40 ton Double Girder Bridge Crane Drawing

We designed the bridge crane solution accordingly. After checking the details, Tony replied "Thank you for your drawing. The crane you have presented looks like it will meet our needs."

The working class quoted here is FEM2M (ISO M5) which is the same class I purchased previously but to be honest my current crane does not seem to be designed for every day use. The previous crane is not used every day so it is not an issue. These new cranes will be used every day 3 shifts per day so we need a more robust system. Are you able to quote an ISO M7 class work duty?

Yes, we can change the working class to M7 which is more suitable for frequent lifting as described. But when we changed the working class to M7 and offered our quotation, Tony replied that they need to go back to the M5 crane due to space constraints. The solution changed back again.

Tony checked the crane span with his team again and found there was a little difference between the two spans. One span is 73ft, but the other one is 72 ft. 8 inches. Although the difference is very small, we must re-modify the design of one of the bridge cranes, otherwise the produced bridge crane cannot be installed on the rails.

Modified 40 ton double girder bridge crane drawing (span is 22.15m)

We also equipped variable speed (inverter controlled) on the cross travel and crane travel as the customer's needs. The variable speed will bring a better sense of experience when operating. The same is true after installation.

After discussing shipping issues, tony's team placed the order. Every Tuesday, we communicate with the customer about the production status of the order. The customer has control over the production progress of the entire order, and it is also convenient for the customer to make reasonable arrangements for the progress of the entire project.

Due to COVID-19, our engineers are unable to provide installation services at the customer's workshop. However, through the installation manual, video and video call, we guided the customer's team to complete the installation of 2 units 40 ton double girder bridge cranes and the cranes work very well. Tony and his team are very satisfied with this cooperation.

United States 40 ton Double Girder Bridge Crane Gallery

About Installation Service

About crane installation service, It's back to normal now. Our engineers' team can go abroad to offer installation service for every customer.

- (Chinese government policy) On January 8, 2023, the new type of coronavirus infection was adjusted from "Class B and A control" to "Class B and B control". This is another major adjustment of the epidemic prevention and control policy since my country began to implement strict Class A prevention and control measures for infectious diseases on January 20, 2020.

- (Chinese government policy) Starting from January 8, 2023, immigration management policies and measures will be optimized: orderly resume the acceptance and approval of ordinary passport applications for Chinese citizens traveling abroad and visits and resume the processing of travel and business visas for mainland residents to go to Hong Kong.

QDX type Top Running Double Girder Overhead Crane Introduction

- Designed with FEM/DIN standards.

- Widely used in machinery fabrication, metallurgical plant auxiliary workshop, storage, etc.

- Lifting Capacity: 1~100t

- Span: 7.5-31.5m

- Lifting Height: 6/9/12/18m (according to your needs)

- Voltage: 220-480V 50/60Hz 3Phase

- Working Class: M5, M6

- Ambient Temperature: -25~40℃

Advantages of Double Girder Overhead Crane

- Double main beams design, more strong

- Large lifting capacity

- Higher working duty

- Higher lifting and travelling speed

- Higher lifting height

- Light weight, light wheel load, reliable performance

Features of Double Girder Overhead Crane

- FEM and GB production standards

- Epoxy zinc-rich primer and chlorinated rubber topcoat

- Pendant control, remote control and cabin control available

- Overload limiter, lifting height limiter, cross travelling limiter and crane long travel limiter are included

- Automatic power-off protection

- Frequency conversion is available for lifting, cross travelling and crane travelling

- Customized overhead crane solution available for special industries

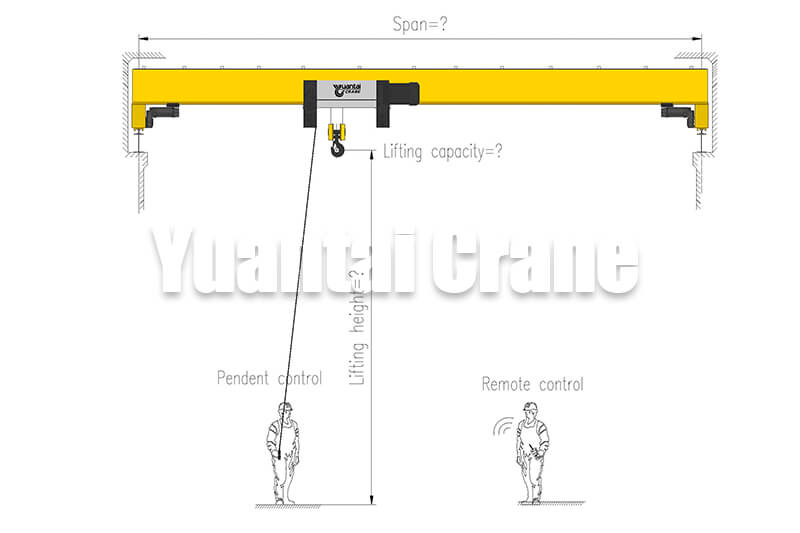

I Need It, How to Get Double Girder Bridge Crane Price and Solution?

We are excited for the opportunity to work with you and find the right solution for your problem, no matter how complex or unique. Our engineering team will create a custom double girder bridge crane for you that has everything you need for effective material handling within your facility. Shop for double girder eot cranes and let us know if you need a custom option, we will work with you to customize a factory overhead crane that meets your needs. It's easier to get overhead crane solution with the request information below.

- Lifting capacity: ____ ton

- Lifting height: ____ m

- Span: ____ m

- Power supply (e.g., 380V 50Hz 3Phase):

- Crane travelling length: ____ m

- Control model: pendant control? remote control? cabin control?

- Shall we provide crane rails and power feeding system?

- Used indoor? Or outdoor?

- Detailed working conditions of the crane:

- Other requirements:

Contact us with above information, quotation will be sent soonest.

United States 40 ton bridge crane main beams

United States 40 ton bridge crane main beams United States 40 ton bridge crane end carriages

United States 40 ton bridge crane end carriages

Get Free Quotation